How Are Lithium-ion Batteries Manufactured?

The global demand for batteries has grown significantly over the few decades because of new electric power tools and consumer electronics like smartphones. Lithium-ion battery technology is planned to provide better and more intelligent power storage solutions for the effective use of renewable energy.

This technology enabled the spurt in growth and revolution in powering tablets and smartphones. Here is an explanation of the manufacturing process involved in the production of Lithium-ion batteries.

Raw Materials involved in the Manufacturing Process

Lithium-ion batteries require high-quality cathode, anode, electrolytes, and separator materials to manufacture a great battery.

Cathode Materials

The cathode materials include lithium-metal oxides, vanadium oxides, rechargeable lithium oxides, and olivines. According to multiple research, layered oxides that contain nickel and cobalt have high stability. This is true in dealing with high voltage ranges. However, cobalt faces challenges in its mass production because of its toxic effects and scarcity in nature.

Manganese is an excellent substitute for cobalt because it is more affordable and has a high thermal threshold. However, manganese possesses challenges in its cycling behavior. Therefore, most manufacturers prefer to use the combination of manganese, cobalt, and nickel to minimize the limitations and get the best properties.

Research shows that vanadium oxides possess a large storage capacity. However, due to the amorphous state of vanadium oxides, their cycling behavior is limited. Although olivines are non-toxic, they have a moderate storage capacity with low conductivity.

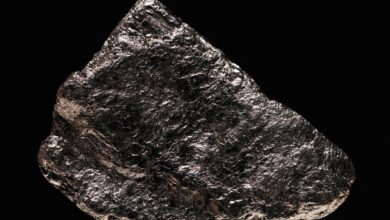

Anode Materials

The materials used to make the anode of lithium-ion battery include graphite, intermetallic, silicon, lithium, and lithium-alloying materials. Although lithium seems the best candidate for making the anode, it suffers from dendritic growth and erratic cycling behavior. These characteristics increase the likelihood of short circuits occurring when lithium is used in the anode.

Most manufacturers prefer carbonaceous anodes because of their ready availability and low cost of production. However, carbonaceous anodes have a low theoretical capacity compared to lithium. Several researchers have tried to boost the capacity by using varieties of graphene and carbon nanotubes. These changes attracted higher production and processing costs.

Although silicon, intermetallic compounds, and alloy anodes have high capacities than lithium, they suffer from poor cycling behavior. Some manufacturers decided to use nanocrystalline material and metal alloy phases to overcome the volume change experienced. The fading capacity of silicon has not been established.

Electrolytes

When a manufacturer wants to build a long-lasting and safe battery, they should ensure the electrolyte can withstand high temperatures and existing voltages. The electrolyte should also offer increased mobility for lithium ions. You will find three main electrolytes: liquid, solid, and polymer-state.

Liquid-state electrolytes are usually organic. Therefore, manufacturers should consider the liquid’s electrochemical performance and flammability. Polymer electrolytes have high resistance and conductivities at high voltages. Solid electrolytes typically need special conditions to be adequate.

Separators

The battery separator is a material that keeps the anode and cathode physically apart. This helps prevent short-circuiting when the two electrodes touch each other. Lithium-ion batteries with a liquid electrolyte usually have foam acting as the separator. An ideal separator should have chemical resistance to degradation in a highly active electrochemical environment.

The separator should have minimal electrolyte resistance and maximum mechanical stability. In addition, an ideal separator should have a safety feature that shuts down the battery when it experiences high temperatures without destroying the mechanical integrity.

The Manufacturing Process

The manufacturing process of Lithium-ion batteries involves four primary steps. Firstly, there is quality control of the materials followed by electrode production. The cell stack assembly, drying, electrolyte filling, aging, formatting, and sorting follows. The last significant step is the assembly of the cells into the lithium-ion battery.

The manufacturing process is delicate because the surface should be made with extreme precision. The maximum allowed deviation of the cell’s surface should be less than 2%. When the deviation exceeds 2%, the battery is more likely to suffer high-performance degradation and becomes hazardous. The primary challenge experienced in manufacturing a battery system is creating a three-dimensional structure out of a two-dimension form.

The manufacturing quality of a lithium-ion battery is a critical determinant of its performance and lifespan. The battery’s quality depends on the quality of materials used, the precision in assembly, and the subsequent quality control. The materials used in manufacturing are sourced from a variety of locations globally.

There are many benefits of Lithium-Ion Batteries, such as high energy density, high power density, no memory effect, and low self-discharge rate. These benefits make them suitable for use in many applications. Lithium ion battery manufacturing can help a country reduce the import dependency on fossil fuels and help build up our economy by creating jobs for people.