Swiss textile machinery firms gear up for ITMA Asia + CITME 2022

China is among the world’s biggest textile markets. The industry there has experienced substantial growth and evolution, becoming a hub for textile production, innovation, and consumption. Swiss machinery manufacturers adapted in the past to the specific market situation and are now ready and able to support the future goals of China’s textile manufacturers, the Swiss Textile Machinery Association said in a press release.

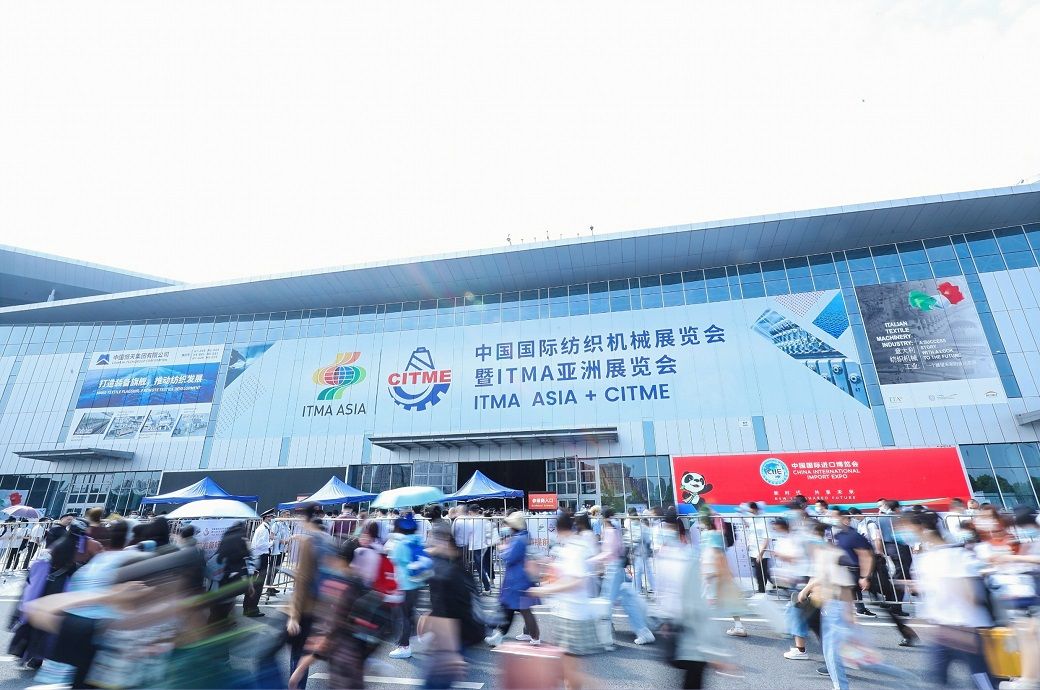

Around 15 members of the Swiss Textile Machinery Association will be participating in the upcoming ITMA Asia + CITME 2022 in Shanghai.

Swiss manufacturers have adapted to China’s evolving textile landscape, emphasising sustainability, new technologies, and digitalisation.

Advanced weaving machinery and sustainable yarn production will remain focal points.

In China, the textile industry is forward-looking and resilient with a healthy appetite for new technologies and a determination to keep its leading position. Sustainability is increasingly coming into focus, so there is a growing demand for recycling technologies, as well as automated solutions and digitalisation.

“China is the main market for a large number of our association members,” said Cornelia Buchwalder, secretary general of the Swiss Textile Machinery Association.

Swiss companies realised many years ago that geographical proximity is the key to success. For example, Staubli has started to set up offices in Chinese cities since 1998 and counts 12 locations today, to serve the whole country. In 2002, Itema established a centralised local branch which today has 160 employees in various functions. Loepfe has expanded its presence by creating an independent local business unit to overcome the 9,000 km distance by air, while Uster Technologies has had a Chinese subsidiary since 1982, with offices and service stations in different provinces. Luwa set up its offices and workshop in Shanghai in 1997. Rieter established a presence in mainland China in 2005, driven by a strong commitment to expanding the country’s know-how and expertise—and 10 years later opened an advanced research centre.

“We are firmly committed to delivering the cutting-edge technology and textile expertise to help the Chinese spinning industry stay at the forefront of innovation,” said Thomas Oetterli, CEO Rieter Group.

All Swiss companies with serious business goals in China have made similar commitments to connect with customers and maintain strong relationships. “Geographical proximity allows the companies to adopt a strong customer-centric approach and provide more effective local installation support, training, and field services to customers,” said Frank Naef, head of marketing, Loepfe Brothers.

Swiss companies also understand that Chinese customers require dedicated attention, and that speed is more essential than ever in delivering both machines and services.

China’s move towards self-sufficiency is a continuing trend. Staubli has developed local products for the Chinese market and built long-standing partnerships with many local companies. “The technical development of the partners goes hand in hand with our local competence, which we have built up in Hangzhou over the years,” said Fritz Legler, textile marketing officer at Staubli. Developments in new technology and automation are taking Chinese mills further into the digital age, with machinery incorporating intelligence and high engineering performance.

Manufacturers in China are seeking cost-effective solutions to remain competitive, while consumers are looking for value in their purchases. Companies need to develop solutions that provide tangible economic benefits to their clients. Furthermore, energy savings have become paramount in China, due to the government’s commitment to environmental sustainability and reduced carbon emissions.

“Businesses are adopting more energy-efficient processes and technologies to meet stringent energy conservation and emission reduction targets,” said Peter Schnickmann, managing director at Luwa Air Engineering (Shanghai). He noted an investment trend for solutions helping Chinese companies cut operational costs and minimise their carbon footprint.

To enhance the reputation of both companies and products—and boost the image of the entire industry—the environmental impact needs to decrease. Priorities are saving water and waste, as well as reducing, replacing, or completely eliminating the use of harmful substances. China has a strong demand for environmental-friendly solutions and sustainable technologies. “China is an important business partner for Benninger demanding salt-free dyeing solutions, water consumption figures, and modern dispensing systems,” said Rolf Erik Schoeler, head of sales and marketing at Benninger Group.

The huge number of Chinese fabric producers calls for an immense volume of weaving machinery to be supplied by international and local providers. Thanks to their customer-oriented approach, Swiss machinery manufacturers hold an impressive share of this business.

Chinese weavers require advanced technology, with increasingly higher standards of efficiency. Swiss Textile Machinery Association members meet these needs in many ways. In weaving preparation, latest solutions match the speed, quality, and reliability now wanted. Weaving machines too offer the eco-efficiency, performance, and ease of use needed, with innovations that extend the scope of sustainable weaving, and open-platform systems configurable to weavers’ specific operations.

It’s important to note that Swiss weaving machinery is appreciated both by major manufacturers and by the smaller companies who need both reliable equipment, as well as expert training and ongoing support.

A huge increase in demand for technical textiles in recent years has been driven by applications such as carbon fibre, aramid and glass fibre. “We will take the occasion of the upcoming ITMA Asia in Shanghai to host an event sharing know-how and experience on technical fabrics,” said Matteo Mutti, managing director at Itema Switzerland.

China’s competitive advantages come from its large-scale and integrated manufacturing capabilities, along with the use of advanced automation and digitisation technologies. Spinners aim to capitalise on extended market opportunities, with more economical production. The latest air-jet spinning machines serve these goals, allowing exceptionally low production costs per kilogramme of yarn, coupled with high flexibility and reliability.

Sustainable yarns are in great demand. Innovative systems from Swiss manufacturers enable spinners to produce fine, high-quality ring and compact yarns from challenging raw material. This holds true even with a relatively high proportion of mechanically recycled cotton fibres.

The automation trend in spinning mills focuses on connecting production processes. Data is used to ensure the highest quality standards, most efficient raw material usage, reduction of waste, and energy savings. To make spinning mills more competitive, latest solutions combine cutting-edge hardware, data-enabled software, and renowned textile expertise.

For many decades, Uster has been working to improve and extend growth and quality management practices in China. “We are happy to have contributed positively to the successes and the reputation of Chinese textile products,” said Sivakumar Narayanan, head of marketing and business development at Uster Technologies.

On top of growing consumer demand and technological capabilities, the latest ambitious five-year plan will drive further development of the Chinese textile industry in world markets, and Swiss companies will work with all stakeholders to enable its success.

Fibre2Fashion News Desk (NB)